Innovative technologies, sourcing of materials, engineering and custom design

Ges Group’s mission is to respond to the increasingly sophisticated and particular needs of a wide range of customers. From the gym to the pool, from the school to hospitals, from the company to campsites: working with many different kinds of buyers is an incentive to constantly find innovative solutions for modular interior design. Ges Group has at its disposal, adequate solutions for every type of job. Over the years, the company has embarked on a research journey into the various characteristics, technological solutions, materials and finishes to provide customers with a product system that is increasingly attentive to different needs.

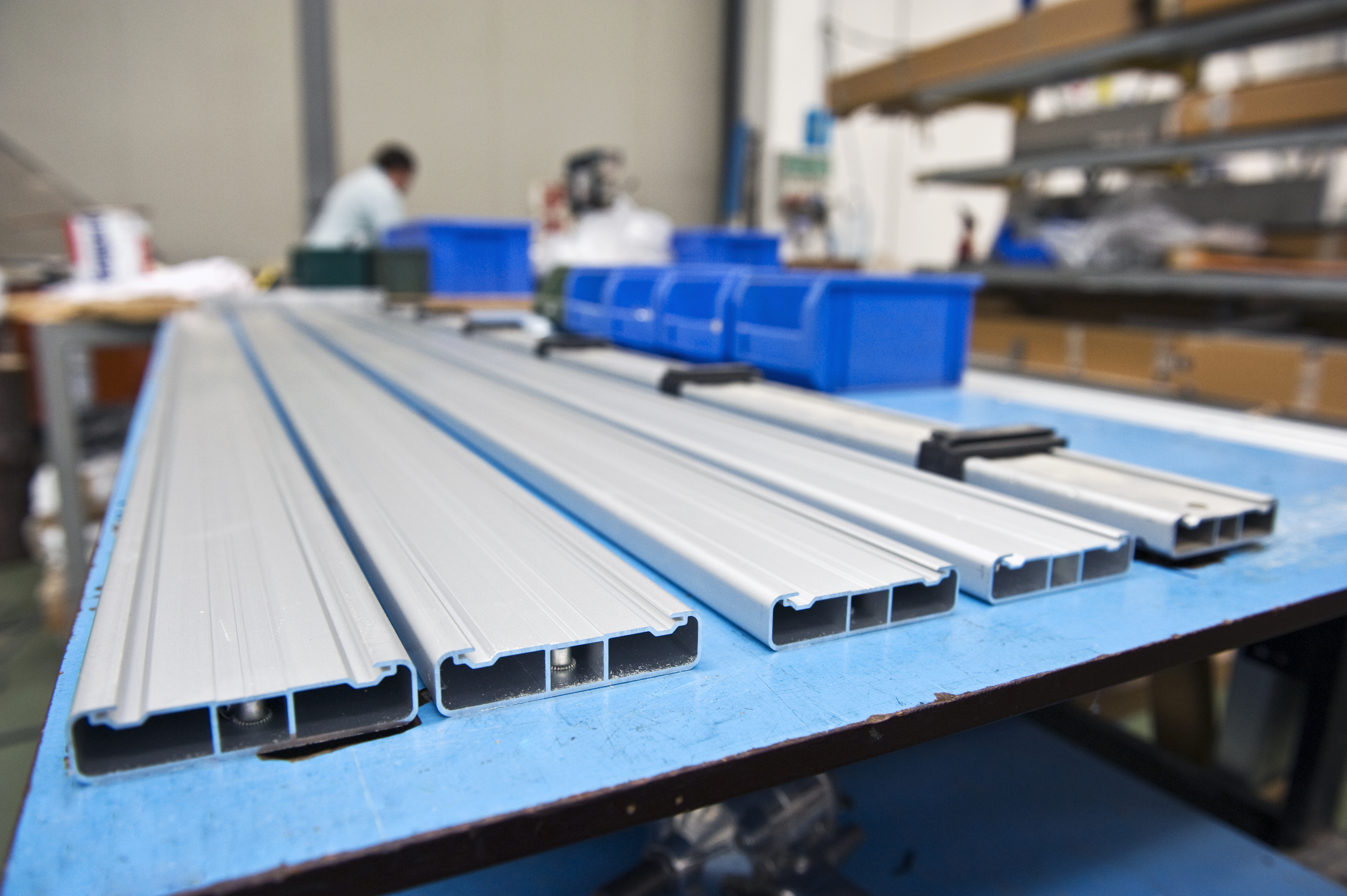

Ges Group products are all built with materials characterised by excellent properties and performance in environments with high levels of moisture and humidity: HPL laminates, ISI 001 anodised aluminium alloys, AISI 304 stainless steel. Among thermoplastics: nylon 6 and PVC reinforced with glass fibres. All materials guarantee durability over time and great practicality in maintenance and cleaning. The simple, linear design easily fits into any environment and modularity and facilitates the organisation of custom-made furniture.

Ges Group articles allow savings on assembly, dismantling and maintenance time and the recovery of useful space. The HPL laminate, in fact, has varying thicknesses: for the modular walls it has a thickness of only 14 mm, compared to 10/12 cm in normal masonry. The high quality of the Ges Group products is guaranteed in all phases of the manufacturing process for furnishings of changing rooms, bathrooms and swimming pools: from design to production, from sales to installation, through to consulting and post-sales customer management.

The company also ensures the resolution of existing structural problems and makes a commercial network available that allows the carrying out of inspections and surveys directly on site, supporting the customer in all of the operations necessary to create the desired changing room environment. The presence of qualified technicians during installation and the subsequent maintenance complete the picture of a cutting-edge operating structure with absolute reliability.

Ges Group offers its customers a “turnkey” service that covers supply at every stage of the project, thus meeting the need of guaranteeing every type of support. Thanks to a network of trusted suppliers, the company is today able to offer assistance ranging from plant engineering down to all the furniture details.

Threespine™ e Alaglide® - Innovative technologies

Ges Group has built its new product range around two technologies, making simplicity and convenience

its key strong points, thanks to the Exclusive Licence for Italy for Threespine® – the Välinge patent that eliminates

the hardware required in the various units and slashes assembly times – and Alaglide – the door opening

and closing technology that reduces space requirements by from 36% to 66%.

Ges Group is a Makte Italia partner for materials research.

Ges Group is a business partner of Makte Italia, the networking organisation of trends, professionals, materials libraries and, above all, products for the architecture and design world. Thanks to Makte Italia, Ges Group enjoys access to a database with an infinity of materials and finishes, for creating any furniture and interior design item.

With the aid of this invaluable partnership, the Verona-based company’s design team will be constantly updated and trained on the latest trend-setting materials, to look to the future with solutions that are more and more innovative, functional and smart.

Engineering of the production cycle and design.

The in-house design department uses state-of-the-art, customised product engineering software packages,

also shared via outsourcing, and aims to achieve a 40% reduction in lead times by optimising the entire design, execution and production process.

The company is also proud to benefit from prestige partnerships with important architects and designers,

who can anticipate market trends and create outstanding product designs for furnishing communal spaces.